Jit is more a way of thinking than an actual technique and it’s based on the idea of making the material arrive when it is needed and not in advance, which is something costing more and being negative for production.

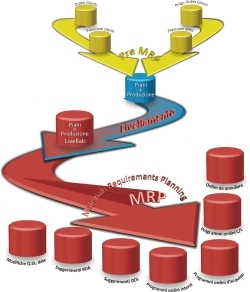

Si5 responds with several features from a punctual scheduling with MRP to short-time pick-up scheduling, in order to favour urgent parts and mostly open order management.

It presents a nonexistent inertia and it is aable to respond promptly to sudden and unexepcted variations of demand. Managing open orders also requires a different way of confronting with the suppliers by achieving comakership relationships.