Management for fiche

Management per lot-tag, essential for materials which must be traced or are expiring, is also useful for stock handling ( per unit of packaging). By operating per lot-tag, it’s not necessary to identify the handled material and its quantity, but it’s sufficient to key on the lot-tag number or read barcode representing the lot-tag number.

Management per lot-tag is set up when the identification has a “pick-up typology” requiring management per lot-tag and when it’s handled in a warehouse needing this type of management. If one of the two conditions are missing, management gives out.

Per lot-tag means :

- A label matching the material

- a collection of information contained in the related file

Lot-tag are generated by all warehouse functions creating, directly or indirectly, a balance such as :

- entries by the supplier

- entries by the client

- declaration of test

- declaration of production

- transfers within warehouses

- positive inventory adjustments

A “document” which is at the same time :

- univocal information managed in an appropriate file of Si5.

- a paper document associated with the material and through which it’s made the whole handling.

- EASIER Material handlings in warehouse

- Enables to manage Traceability

- Enables to manage expiring materials

Be able to read Fiches

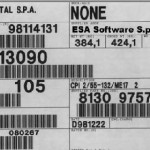

The fiche Fiche p has got an own univocal identification element which is made of:

- Types of fiche

- Progressive Number in the Fiche

In the paper document the number of fiches is reported other than in literal form, as in Barcodes, used for material handlings.

- Plant

- Number of the Fiche

- Condition of the Fiche

- Identificaton

- Expected Quantity

- Entered Quantity

- Current Quantity

- Stock

- Lot – Type of Lot – Location

- Batch

- Container Code

- Work orders

- Supplier

- purchase item order

- Client

- client item order

- Ex type and number of Fiche

- Bill

- Expiring Date

Management of barcodes flow

The unit enables generation and printouts of labels and barcodes. The whole material flow, from check-in to good booked-into stock, to picking up, to production payments and shipments, is followed in automatic through barcode read.

The unit make easier to manage traceability of materials through batch labels (lot-tag), by supporting, for necessary transactions, different hardware tools, from optic pens to laser guns charging and discharging (batch), to the most innovative tools in radiofrequency.